东莞市爱多电子有限公司代理销售各式型号电阻式微型电流保险管,其体积小,外形像插件电阻式样,可以按照空间特性弯角整形成各式形状插脚进PCB上面,操作方便,安全可靠。

其具体规格如下:

一、

2T 3*8电阻式微型/环氧树脂/慢断微型电流保险丝

产品详情

1.规格型号和安规认证

MODEL NUMBER AND

SAFETY CERTIFICATION

1-1 品名规格:系列号+额定电流+额定电压+认证符号

Model Number: Part

Number+Rated Current+Rated Voltage+Approvals.

例子[example]:

2T 1.2

250V

1)系列号Part

Number

2) 额定电流 Rated Current

1)

2)

3)

3) 额定电压 Rated Voltage

1-2额定电流和额定电压

Rated Current And Voltage

额定电流: 32mA~1

Rated Current: 32 mA~1

额定电压;125V/250V/400V

AC

Rated Voltage:125V/250V/400 AC

1-3标示Marking

保险管上需有下列标示

The fuse shall have the following marking:

规格:特性符号+额定电流+额定电压

Specification:Characteristic Symbol+Rated Voltage

32mA~800mA : _mA 1A~1:_A

Trade mark:The Manufacture’s Logo+Part

Number+Approvals

32mA~1:UL CSA

注意:对标示字样大小没有规定

Note:Size of the markings have not be specified.

2.适用范围

SCOPE

适用于一般电子设备。Used in electronic equipment.

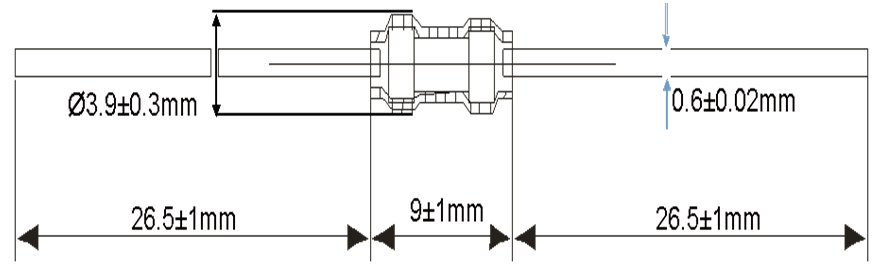

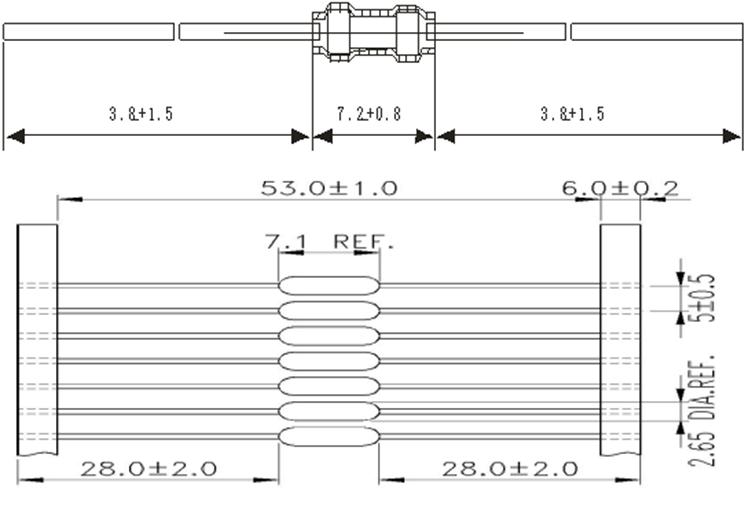

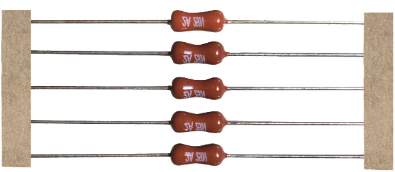

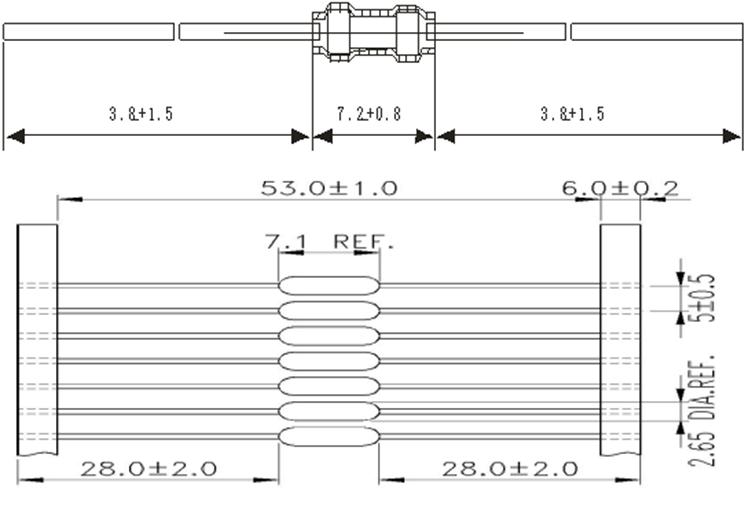

3.工程图和结构

OUTLINE DRAWING AND STRUCTURE

3-1 工程图(單位:mm)

Outline Drawing and Dimensions(Unit:mm)

3-2结构

Structure

|

编号

No.

|

元件

Component

|

材質

Material

|

數量

Quantity

|

|

(1)

|

熔絲

Wire

|

合金

Alloy

|

1

|

|

(2)

|

銅帽

Cap

|

黃銅鍍鎳

Brass with mickel

plated

|

2

|

|

(3)

|

本體

Body

|

陶瓷管/胶料

Ceramic Tube/Plastic

|

1

|

|

(4)

|

引線

Lead

|

鍍錫銅線

Tinned Copper wire

|

2

|

|

(5)

|

镀层

Insulating Coat

|

环氧树脂

Epoxy Resin

|

/

|

4.外觀及形狀

APPEARANCES AND CONFIGURATION

4-1外觀:外观不应有显著的污点、铁锈或者裂纹

Appearances:There shall not be any remaekable stain,rust

or crack on the appearances.

4-2形狀:轴向引脚的超小型保险丝

Configuration:Axial Leaded Micro-Fuse.

5.物理特性

PHYSICAL CHARACTERISTIC

5-1 拉力測試

Tensile test

沿端子的軸向施加10N的拉力,持續1分鐘。

Keep pulling the cap of the fuse with 10N at axial

direction for 1 min.

6.電氣特性

ELECTRICAL CHARACTERISTICS

|

% of Ampere Rating

|

Ampere Rating

|

Opening Time

|

|

100%

|

32mA - 1

|

4 Hours, Min.

|

|

200%

|

32mA - 1

|

60 Second, Max

|

|

275%

|

500mA~ 10A

|

300 msecs., Max.

|

|

400%

|

500mA~ 10A

|

30 msecs., Max.

|

|

1000%

|

500mA~ 10A

|

4 msecs., Max.

|

|

规格判定Item

|

|

Openrating Temp

|

-55℃~125℃

|

|

大熔断时限

|

200% Rating 60SEC

|

|

突波实验

|

3millisecond at 1000%

rated current

|

|

Melting I 2 t

|

1.83~2.083

|

|

Cold Ohms

|

1.2/0.058~0.067 Ohm

|

|

Interrupting rating

|

50A/125VAC

50A/250VAC

|

|

Dimensions

|

9mm*¢3.9mm

|

|

Ssfty

|

UL CSA CCC ROHS

|

7.環境特性

ENVIRONMENTAL SPECIFICATION

7-1 操作溫度範圍:-55℃~125℃

Operating Temperature: -55℃~125℃

7-2 保存條件

Storage Conditions

溫度:+10℃~60℃

Temperature: +10℃~60℃

在相對濕度≤75%下平均可存放3年

On average, It can be stored below the relative humidity

or 75% for 3 years.

在非露天下,相對濕度為95%下多可存放30天。

Without dew, It can be kept under humidity of 95% for 30

days.

8.焊接條件

SOLDERING PAAMETERS

8-1波峰焊

Wave Solder

焊接溫度:260±5℃

Soldering Temperature:260±5℃

焊接時間:4 Sec. Max.

Soldering Time:4 Sec.Max.

8-2手工焊錫

Manual Solder

焊接溫度:350±5℃

Soldering Temperature: 350±5℃

焊接時間:3 Sec. Max.

Soldering Time: 3 Sec. Max.

9.其他使用注意事項

OTHER NOTICE IN USING

如果需在保險絲上加熱縮套管,烘烤溫度與時間需參照以下規定

If heat shrink tubing was needed,the roast temperature

and time should be refer to the following.

設定烘烤溫度:不大於150℃ 烘烤時間:50s Max.

The temperature should be sel under 150℃,roast time:50s

Max.

二、2F-3x8

电阻式 快断 陶瓷保险管

产品详情

1.规格型号和安规认证

MODEL NUMBER AND SAFETY

CERTIFICATION

1-1 品名规格:系列号+额定电流+额定电压+认证符号

Model Number: Part

Number+Rated Current+Rated Voltage+Approvals.

例子[example]:

2T

2A 400V

1)系列号 Part Number

2)额定电流 Rated Current

1) 2) 3)

3)额定电压 Rated Voltage

1-2额定电流和额定电压

Rated Current And Voltage

额定电流: 100mA~10A

Rated Current: 32 mA~1

额定电压;125V/250V/400V AC

Rated Voltage:125V/250V/400 AC

1-3标示Marking

保险管上需有下列标示

The fuse shall have the following

marking:

规格:特性符号+额定电流+额定电压

Specification:Characteristic

Symbol+Rated Voltage

100mA~800mA :

_mA 1A~10A:_A

Trade mark:The

Manufacture’s Logo+Part Number+Approvals

100mA~10A: TUV UL

CSA CQC

注意:对标示字样大小没有规定

Note:Size of the markings have not be

specified.

2.适用范围

SCOPE

适用于一般电子设备。Used in electronic equipment.

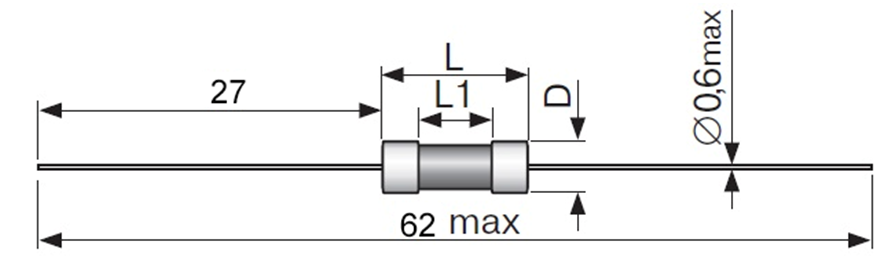

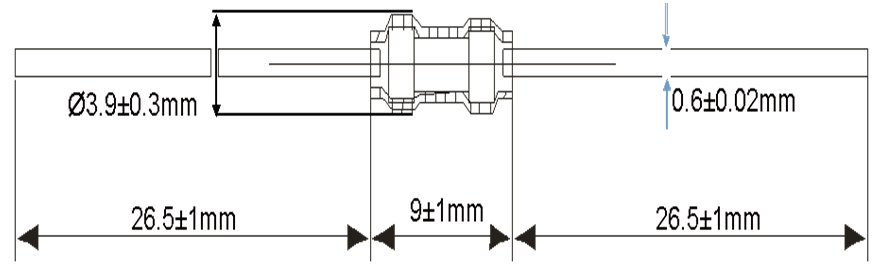

3.工程图和结构

OUTLINE DRAWING AND STRUCTURE

3-1 工程图(單位:mm)

Outline Drawing and Dimensions(Unit:mm)

3-2结构Structure

|

编号

No.

|

元件

Component

|

材质

Material

|

数量

Quantity

|

|

(1)

|

熔丝

Wire

|

合金

Alloy

|

1

|

|

(2)

|

铜帽

Cap

|

黄铜镀镍

Brass with mickel plated

|

2

|

|

(3)

|

本体

Body

|

陶瓷管

Ceramic Tube

|

1

|

|

(4)

|

引线

Lead

|

镀锡铜线

Tinned Copper wire

|

2

|

4.外观及形状

APPEARANCES AND CONFIGURATION

4-1外观:外观不应有显著的污点、铁锈或者裂纹

Appearances:There shall not be any

remaekable stain,rust or crack on the appearances.

4-2形狀:轴向引脚的超小型保险丝

Configuration:Axial Leaded Micro-Fuse.

5.物理特性

PHYSICAL CHARACTERISTIC

5-1 拉力測試

Tensile test

沿端子的轴向施加10N的拉力,持续1分鐘,管体不断开、破裂。

Keep pulling the cap of the fuse with

10N at axial direction for 1 min,and the pipe body is continuously opened

and broken.

5-2管体强度测试

Strength of fuse tube

保险管管体固定好后,在管体中央部位施加15N压力,管体不断开、破裂。

After the fuse pipe body is fixed, the

15N pressure is applied to the center position of the pipe body, and the pipe

body is continuously opened and broken.

6.电气特性

ELECTRICAL CHARACTERISTICS

|

% of

Ampere Rating

|

Ampere

Rating

|

Opening

Time

|

|

100%

|

100mA -

10A

|

4 Hours,

Min.

|

|

200%

|

100mA -

10A

|

60 Second,

Max

|

|

275%

|

500mA~ 10A

|

300

msecs., Max.

|

|

400%

|

500mA~ 10A

|

30 msecs.,

Max.

|

|

1000%

|

500mA~ 10A

|

4 msecs.,

Max.

|

7.环境特性

ENVIRONMENTAL SPECIFICATION

7-1 操作温度范围:-55℃~125℃

Operating Temperature: -55℃~125℃

7-2 保存条件

Storage Conditions

温度:+10℃~60℃

Temperature: +10℃~60℃

在相对湿度≤75%下平均可存放3年

On average, It can be stored below the

relative humidity or 75% for 3 years.

在非露天下,相对湿度为95%下多可存放30天。

Without dew, It can be kept under

humidity of 95% for 30 days.

8.焊接条件

SOLDERING PAAMETERS

8-1波峰焊

Wave Solder

焊接溫度:260±5℃

Soldering Temperature:260±5℃

焊接时间:4 Sec. Max.

Soldering Time:4 Sec.Max.

8-2手工焊锡

Manual Solder

焊接温度:350±5℃

Soldering Temperature: 350±5℃

焊接时间:3 Sec. Max.

Soldering Time: 3 Sec. Max.

9.其他使用注意事项

OTHER NOTICE IN USING

如果需在保险管上加热缩套管,烘烤温度与时间需参照以下规定

If heat shrink tubing was needed,the

roast temperature and time should be refer to the following.

设定烘烤温度:不大于150℃ 烘烤時間:50s Max.

The temperature should be sel under 150℃,roast

time:50s Max.

三、2.4X7电阻式 慢断 微型环氧树脂保险丝 TUV UL CSA CQC

产品详情

1.规格型号和安规认证

MODEL NUMBER AND SAFETY

CERTIFICATION

1-1 品名规格:系列号+额定电流+额定电压+认证符号

Model Number: Part

Number+Rated Current+Rated Voltage+Approvals.

例子[example]:

2SMT/2T

2A 400V 1)系列号 Part

Number

2)额定电流 Rated Current

1) 2) 3) 3)额定电压 Rated Voltage

1-2额定电流 和额定电压

Rated Current And Voltage

额定电流 : 32mA~1

Rated Current: 32 mA~1

额定电压;125V/250V/400V AC

Rated Voltage:125V/250V/400 AC

1-3标示Marking

保险管上需要有下列标示

The fuse shall have the following

marking:

规格:特性符号+额定电流+额定电压

Specification:Characteristic

Symbol+Rated Voltage

32mA~800mA : _mA

1A~1:_A

Trade mark:The

Manufacture’s Logo+Part Number+Approvals

32mA~1: TUV UL CSA

CQC

注意:对标示字样大小没有规定

Note:Size of the markings have not be

specified.

2.适用范围

SCOPE

适用于一般电子设备。Used in electronic equipment.

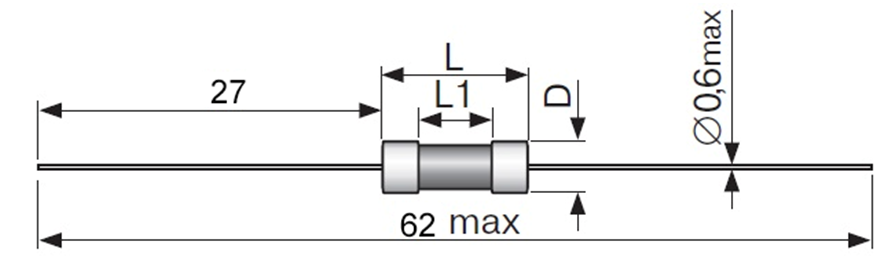

3.工程图和结构

OUTLINE DRAWING AND STRUCTURE

3-1 工程图(單位:mm)

Outline Drawing and Dimensions(Unit:mm)

3-2结构Structure

|

编号

No.

|

元件

Component

|

材质

Material

|

数量

Quantity

|

|

(1)

|

熔丝

Wire

|

合金

Alloy

|

1

|

|

(2)

|

铜帽

Cap

|

黄铜镀镍

Brass with mickel plated

|

2

|

|

(3)

|

本体

Body

|

陶瓷管/胶料

Ceramic Tube/Plastic

|

1

|

|

(4)

|

引线

Lead

|

镀锡铜线

Tinned Copper wire

|

2

|

4.外观及形状

APPEARANCES AND CONFIGURATION

4-1外观:外观不应有显著的污点、铁锈或者裂纹

Appearances:There shall not be any

remaekable stain,rust or crack on the appearances.

4-2形状:轴向引脚的超小型保险丝

Configuration:Axial Leaded Micro-Fuse.

5.物理特性

PHYSICAL CHARACTERISTIC

5-1 拉力测试

Tensile test

沿端子的轴向施加10N的拉力,持续1分鐘,管体不断开、破裂。

Keep pulling the cap of the fuse with

10N at axial direction for 1 min,and the pipe body is continuously opened

and broken.

5-2管体强度测试

Strength of fuse tube

保险管管体固定好后,在管体中央部位施加15N压力,管体不断开、破裂。

After the fuse pipe body is fixed, the

15N pressure is applied to the center position of the pipe body, and the pipe

body is continuously opened and broken.

6.電气特性

ELECTRICAL CHARACTERISTICS

|

% of Ampere Rating

|

Ampere Rating

|

Opening Time

|

|

100%

|

32mA - 1

|

4 Hours, Min.

|

|

200%

|

32mA - 1

|

60 Second, Max

|

|

275%

|

500mA~ 10A

|

300 msecs., Max.

|

|

400%

|

500mA~ 10A

|

30 msecs., Max.

|

|

1000%

|

500mA~ 10A

|

4 msecs., Max.

|

|

规格判定Item

|

系统AVL1

|

2nd souece(AVL2)

|

|

TAPYE

|

Slo-Blo

|

无资料

|

|

Openrating Temp

|

-55℃~125℃

|

-55℃~125℃

|

|

Temp.derating Currev

|

无资料

|

无资料

|

|

大熔断时限

|

200% Rating 60SEC

|

60sec MAX(小于60秒)

|

|

突波实验

|

3millisecond at 1000% rated current

|

3millisecond at 1000% rated current

|

|

Melting I 2 t

|

3.14

|

3.14

|

|

Cold Ohms

|

1A/0.13~0.15 Ohm

|

1A/0.13~0.15 Ohm

|

|

Interrupting rating

|

50A/125VAC

50A/250VAC

|

50A/250VAC

|

|

50A/400VAC

|

|

Dimensions

|

7.2mm*¢2.6mm

|

7.2mm*¢2.6mm

|

|

Ssfty

|

UL CSA

|

CCC

|

7.环境特性

ENVIRONMENTAL SPECIFICATION

7-1 操作温度范围:-55℃~125℃

Operating Temperature: -55℃~125℃

7-2 保存条件

Storage Conditions

温度:+10℃~60℃

Temperature: +10℃~60℃

在相对湿度≤75%下平均可存放3年

On average, It can be stored below the

relative humidity or 75% for 3 years.

在非露天下,相对湿度为95%下多可存放30天。

Without dew, It can be kept under

humidity of 95% for 30 days.

8.焊接条件

SOLDERING PAAMETERS

8-1波峰焊

Wave Solder

焊接温度:260±5℃

Soldering Temperature:260±5℃

焊接时间:4 Sec. Max.

Soldering Time:4 Sec.Max.

8-2手工焊锡

Manual Solder

焊接温度:350±5℃

Soldering Temperature: 350±5℃

焊接时间:3 Sec. Max.

Soldering Time: 3 Sec. Max.

9.其他使用注意事项

OTHER NOTICE IN USING

如果需在保险管上加热缩套管,烘烤温度与时间需要参照以下规定

If heat shrink tubing was needed,the

roast temperature and time should be refer to the following.

设定烘烤温度:不大于150℃ 烘烤时间:50s Max.

The temperature should be sel under

150℃,roast time:50s Max.

|