DYE Fuse DF Series Specification as below:

|

PAPT NO.

|

Tf(℃)

|

Th(℃)

|

Tm:VDE(UL)

|

EK

|

UL/CUL

|

VDE

|

CCC

|

PSE

|

|

DF50S

|

50

|

30

|

130

|

—

|

—

|

—

|

—

|

●

|

|

DF57S

|

57

|

37

|

130

|

—

|

—

|

—

|

—

|

●

|

|

DF66S

|

66

|

42

|

110(130)

|

●

|

●

|

●

|

●

|

●

|

|

DF72S

|

72

|

50

|

115(110)

|

●

|

●

|

●

|

●

|

●

|

|

DF77S

|

77

|

55

|

120(110)

|

●

|

●

|

●

|

●

|

●

|

|

DF84S

|

84

|

60

|

125(114)

|

●

|

●

|

●

|

●

|

●

|

|

DF91S

|

91

|

67

|

135(121)

|

●

|

●

|

●

|

●

|

●

|

|

DF98S

|

98

|

76

|

140(130)

|

●

|

●

|

●

|

●

|

●

|

|

DF100S

|

100

|

78

|

135(250)

|

●

|

●

|

●

|

●

|

●

|

|

DF104S

|

104

|

80

|

150

|

●

|

●

|

●

|

●

|

●

|

|

DF110S

|

110

|

88

|

140

|

●

|

●

|

●

|

●

|

●

|

|

DF115S

|

115

|

95

|

170

|

—

|

—

|

—

|

—

|

●

|

|

DF119S

|

119

|

95

|

170

|

●

|

●

|

●

|

●

|

●

|

|

DF121S

|

121

|

95

|

170

|

—

|

—

|

—

|

—

|

●

|

|

DF128S

|

128

|

106

|

155

|

●

|

●

|

●

|

●

|

●

|

|

DF132S

|

132

|

110

|

155

|

—

|

—

|

—

|

—

|

●

|

|

DF139S

|

139

|

117

|

170

|

●

|

●

|

—

|

—

|

●

|

|

DF141S

|

141

|

117

|

171

|

●

|

●

|

●

|

●

|

●

|

|

DF144S

|

144

|

120

|

250

|

●

|

●

|

●

|

●

|

●

|

|

DF152S

|

152

|

128

|

176(175)

|

●

|

●

|

●

|

●

|

●

|

|

DF167S

|

167

|

142

|

210

|

●

|

●

|

—

|

—

|

●

|

|

DF169S

|

169

|

145

|

300

|

●

|

—

|

—

|

—

|

●

|

|

DF170S

|

170

|

146

|

300(190)

|

●

|

●

|

●

|

●

|

●

|

|

DF179S

|

179

|

155

|

300

|

●

|

—

|

—

|

—

|

●

|

|

DF184S

|

184

|

160

|

300(214)

|

●

|

●

|

●

|

●

|

●

|

|

DF192S

|

192

|

162

|

290(222)

|

●

|

●

|

●

|

●

|

●

|

|

DF216S

|

216

|

—

|

241

|

●

|

—

|

●

|

●

|

●

|

|

DF222S

|

222

|

195

|

300

|

●

|

—

|

—

|

—

|

●

|

|

DF228S

|

228

|

193

|

300

|

●

|

●

|

●

|

●

|

●

|

|

DF240S

|

240

|

200

|

290(260)

|

●

|

●

|

●

|

●

|

●

|

|

DF260S

|

260

|

220

|

350

|

●

|

—

|

—

|

—

|

●

|

|

DF280S

|

280

|

230

|

350

|

●

|

—

|

—

|

—

|

●

|

file NO .EK:HH05009-2001A-2019A.5020A-5023A

UL/CUL:E117626

10. SOLDERABILITY

1) CONTACT LEAD

Soldering Bath Temperature ; 300℃

Immersing depth ; 2mm

VDE:40017388

PSE:JET2926-32001-1001-1011

CCC:2003010205079617

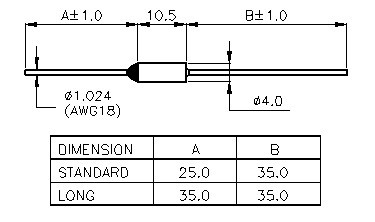

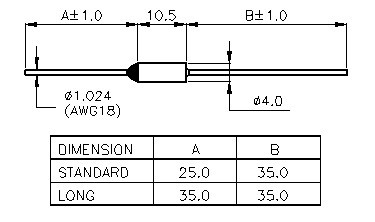

2. DIMENSIONS

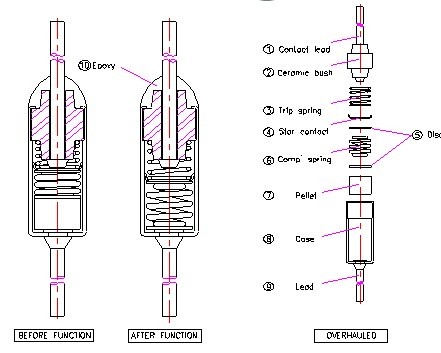

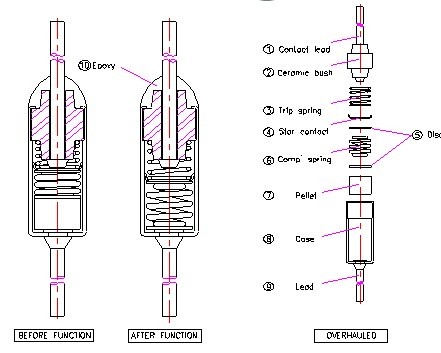

3. OPERATING PRINCIPLE & CONSTRUCTIONS

|

NO

|

DESCRIPTION

|

RAW MATERIAL

|

REMARKS

|

|

1

|

CONTACT LEAD

|

COPPER WIRE

|

SILVER-PLATED

|

|

2

|

CERAMIC BUSH

|

CERAMIC

|

|

|

3

|

TRIP SPRING

|

STAINLESS STEEL WIRE

|

|

|

4

|

STAR CONTACT

|

SILVER STRIP

|

|

|

5

|

DISC

|

PHOSPHOR BRONZE STRIP

|

|

|

6

|

COMPRESSION SPRING

|

STAINLESS STEEL WIRE

|

|

|

7

|

THERMAL PELLET

|

ORGANIC CHEMICAL

|

|

|

8

|

CASE

|

YELLOW BRASS STRIP

|

SILVER-PLATED

|

|

9

|

LEAD

|

COPPER WIRE

|

|

|

10

|

SEAL

|

EPOXY

|

|

4. CALIBRATION VERIFICATION

a. The samples of TCO are to be tested using electrically heated static-air oven.

b. Equilibrium conditions of oven temperature prior to the starting of the test are

to be established 10℃ below the rated Tf for 2 hours.

c. The temperature is then to be increased at a rate of 0.5℃/minute until the

TCO opened.

d. The opening temperature of each TCO shall not differ by more than plus 0℃

and minus 5℃ from the rated Tf.

5. THERMAL ELEMENT STABILITY(Aging)TEST

TCO are to be subjected to the following series of tests. Each sample shall

function at some time during the test steps.

Samples remaining intact at the conclusion of each step are to be submitted

to the next step.

STEP 1.

The samples are to be subjected to a temperature Tf minus 15℃ for 3weeks.

At the conclusion, at least 50% of the samples shall not have functioned.

STEP 2.

Tf minus 10℃ for 2 weeks

STEP 3.

Tf minus 5℃ for 1 week

STEP 4

Tf minus 3℃ for 1 week

STEP 5.

Tf plus 3℃ for 24hours

6. INSULATION RESISTANCE

Affer the fusing test of TCO, insulation resistance between lead and contact lead of

the test sample shall be more than 0.2MΩ. The insulation resistance to be

measured with a DC voltage of twice the rated voltage.

7. DIELECTRIC VOLTAGE WITHSTAND

TCO shall withstand for 1 minute without breakdown a 60Hz essentially

sinusoidal potential twice the rated voltage applied between leads or terminals

of an opened TCO.

8. DIELECTRIC RESISTANCE

Dielectric resistance measurement to be done between both leads at the

distance of 30mm including the body. Dielectric resistance shall be more than

1.5mΩ.

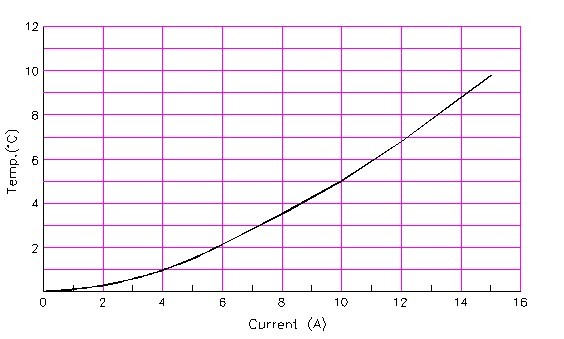

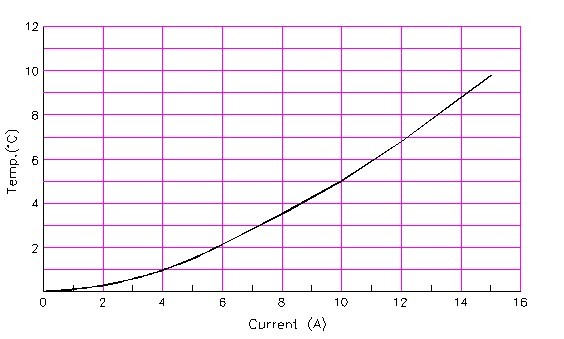

9. TEMPERATURE RISE

Temperature rising of TCO shall be not more than 10℃, when the r

rated

current to be passed through the TCO.

|